2023.03.02

Switching to Clean Power in Suspension Spring Manufacture to Bring Major CO2 Reduction

The suspension leaf springs manufactured by Mitsubishi Steel command a share of some 25% of the domestic market thanks to the synergistic effect existing between the company’s main strengths, the special steel bars business and the springs business. At the leaf spring manufacturing base in Indonesia, the company is aiming to supply, by the second half of the 2020s, eco-friendly products that achieve a major reduction in carbon emissions in their manufacture. Leaf springs are manufactured in a continuous process in Indonesia, but electric furnaces are part of the production of steel, leading to higher carbon emissions. The company is therefore planning to switch to the use of clean electricity generated by renewable resources to power the furnaces. Since the manufacturing process uses fossil fuels in areas other than the generation of electricity, it is not possible to reduce such emissions to zero, but they can be cut by between 60% and 80% from current levels. The company is also working toward a further reduction in carbon emissions through the utilization of hydrogen, ammonia and other low-carbon fuels.

The Mitsubishi Steel head office

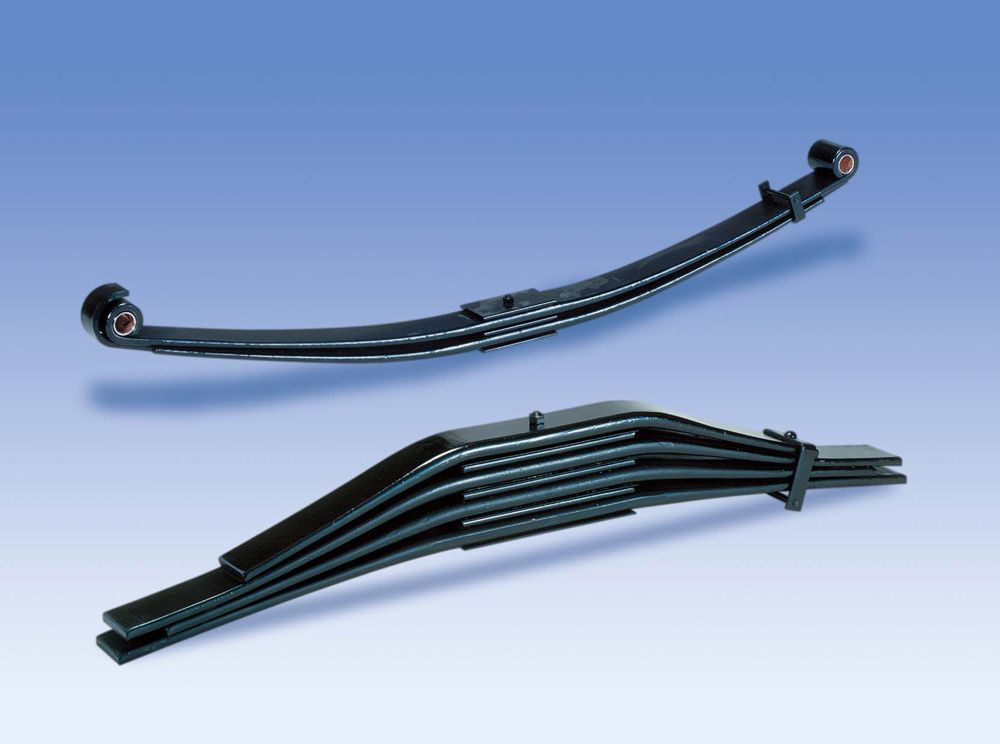

Leaf springs used in commercial vehicle suspension systems

The Mitsubishi Steel head office

Leaf springs used in commercial vehicle suspension systems