2023.08.24

Paper to Outstrip Plastic! Mitsubishi Paper Mills Develops Coated Packaging Paper with Outstanding Barrier Properties

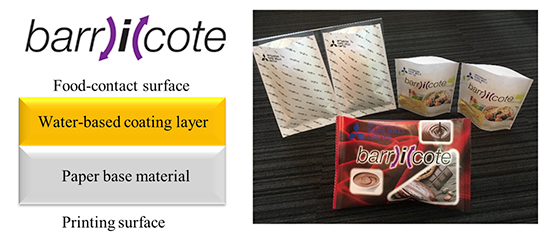

barricote® is employed for outer packaging.

barricote® is employed for outer packaging.

The distinct raisin-like fruity aroma of cacao beans wafts out of the package the moment it is torn open. For those who experience this delightful sensation, it may come as a surprise that DO Cacao chocolate, Lotte’s high-end chocolate brand, comes in an all-paper wrapper. When food packaging requires barrier functions such as the need to contain aroma, most manufacturers turn to aluminum foil and vapor-deposited aluminum bags (made from plastic film that is coated with aluminum using a technique called vapor deposition). For DO Cacao, however, Lotte decided to pursue sustainability across the entire value chain by adopting paper packaging coated with barricote®. Made by Mitsubishi Paper Mills, the product has the conventional biodegradability and recyclability of paper but also features heat-sealability and barrier functions against water vapor and oxygen.

In 2023, Mitsubishi Paper Mills’ barrisherpa®, which is barricote® laminated with plastic

film, was adopted by Doutor Coffee as packaging for its limited-edition Hatsugama roasted

coffee. Because protecting the aroma is vital for coffee products, they are usually packaged

in vapor-deposited aluminum bags. By employing barrisherpa®, however, the coffee purveyor

was able to prevent the permeation of oxygen, water vapor and fragrance and retain the aroma

and freshness of the beans while at the same time eliminating the use of aluminum and

reducing the use of plastic.

barricote® and barrisherpa® packaging products have been on the market since 2020. As an

environmentally friendly coated paper product, barricote® has all the biodegradability and

recyclability of paper. With its superior barrier functions and heat-sealability, it can be

used as soft packaging for food products, daily items and sanitary goods. barrisherpa®,

meanwhile, uses only a minimal amount of plant-derived biodegradable plastic film to provide

it with superior strength, water resistance and heat-sealability features, thereby achieving

both biodegradability and barrier properties. Both products serve as alternative materials

that contribute to the reduction of waste plastic.

Aiming for global expansion based on long-standing R&D

Yoshimi Ikezawa of the Sustainable Fiber Materials Development Department, Research and

Development Division was involved in the development of the products and is keen to talk

about their strengths.

“Our subsidiary in Germany, Mitsubishi HiTec Paper Europe GmbH, embarked on the R&D for

barricote® in 2015,” he explained. “In 2019, the paper packaging material was adopted by

major European food manufacturers. Building on this long-standing R&D and track record,

Mitsubishi Paper Mills is continuing with the development to meet the demanding quality

standards in Japan. Among different coated packaging paper developed by paper mill

companies, barricote®, despite being plastic filmless, is characterized by a water-based

coating that achieves barrier functions against oxygen and water vapor and a

heat-sealability quality comparable to plastic film. We intend to keep up with our

development efforts while aiming to enhance environmental friendliness so as to propose

products that meet market needs.”

Yet cost remains an issue. Can the cost of barricote® be reduced to a level comparable to

that of plastic without compromising the high quality of the product? Toshiari Tanaka at the

Sustainable Fiber Materials Sales Department, Sustainable Fiber Materials Division is

committed to try. With an eye toward mass production, he says they will “work hard to reduce

costs.”

“Toward the goal of achieving a sustainable world,” he continues, “paper mills and all

related industry players must join hands to engage global companies as well as

environmentally conscious small stores in our endeavor to transform society.”

Adds Mr. Ikezawa: “We would like to collaborate with printing converters, packaging device

manufacturers and all other parties across the packaging value chain to make new proposals

to the market. To this end, we are determined to deliver high-quality materials.”

As a leader of the paper manufacturing and packaging industries, Mitsubishi Paper Mills will

focus on global expansion and continue to strengthen its collaboration with the German

subsidiary to develop and produce an extensive lineup of paper packaging products with a

wide range of applications that will take the world by surprise.

INTERVIEWEE

YOSHIMI IKEZAWA

Sustainable Fiber Materials Development Department, Research and Development Division

TOSHIARI TANAKA

Sustainable Fiber Materials Sales Department, Sustainable Fiber Materials Division

Mitsubishi Paper Mills Limited

2-10-14 Ryogoku, Sumida-ku, Tokyo

Founded in 1898. Develops and markets products that contribute to the achievement of

a safe, comfortable and sustainable society in a wide range of fields related to

functional non-woven fabrics, electronics and healthcare, among others. In addition,

the company procures FSC®-certified wood from appropriately managed forests to

expand its pulp business and is developing plastic-free products and distinctive

paper products by building on its papermaking/coating technology that has been

applied to produce printing/communication paper.