2023.12.21

Prodigious materials developed by Mitsubishi Chemical Group Co., offered to space! Supporting the world’s smallest-ever lunar rover

The YAOKI is a lunar rover characterized by its distinctively small size and lightweight

design. Tiny enough to easily fit in the palm of your hand, it is the world’s smallest-ever

lunar rover yet is able to navigate rough terrain and overcome any obstacle. Mitsubishi

Chemical Group Corporation (MCG) is supporting the development of the lunar vehicle based on

a partnership agreement with Dymon Co., Ltd., the startup developer of the mission, which is

scheduled to carry out its first launch in the second half of fiscal 2023.

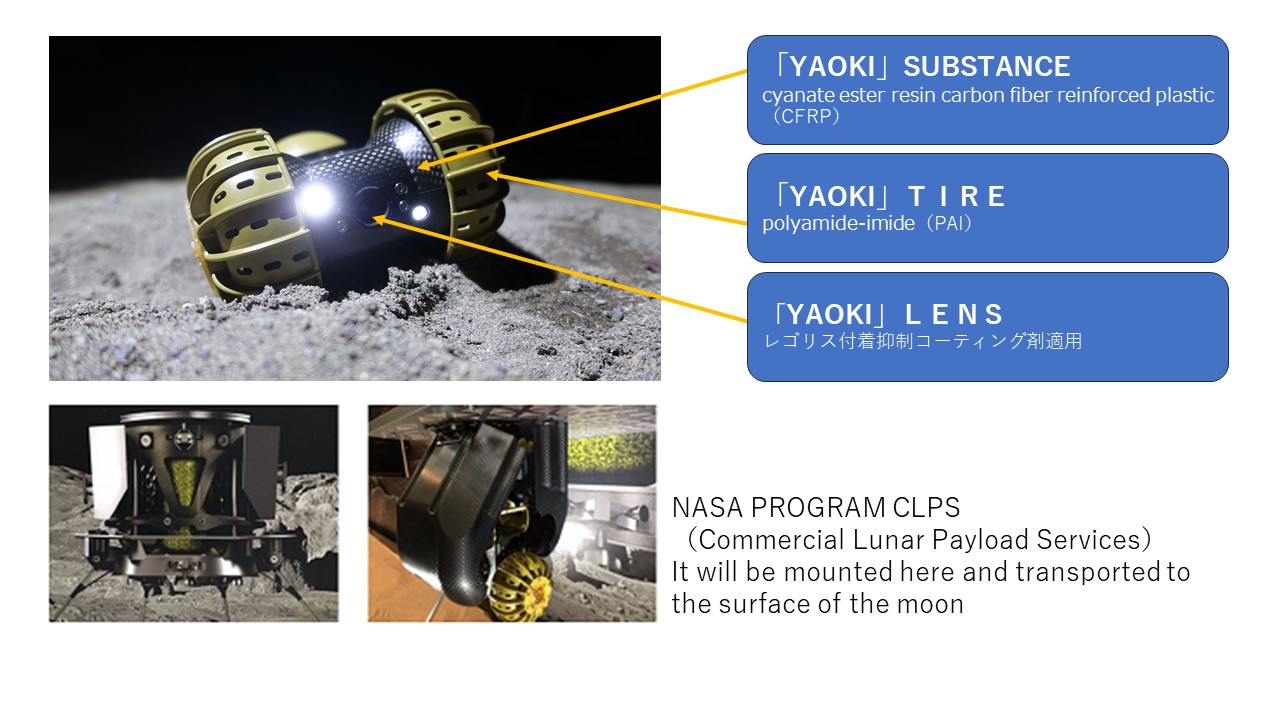

MCG is providing a number of its proprietary materials to the mission. They include cyanate

ester resin carbon fiber reinforced plastic (CFRP) material used for the vehicle body and

polyamide-imide (PAI), a super engineering plastic with high impact strength, to be used in

the tires. These materials have been adopted for their superior durability to withstand the

harsh environment of the lunar surface, which is characterized by large daily temperature

fluctuations of more than 200°C, with daytime highs of up to 110°C and nighttime lows of

−170°C.

MCG’s materials help reduce the YAOKI’s weight, which is only 498 g per unit. This has been

made possible by using CFRP for the vehicle body, which is 30% lighter but with five times

the impact strength compared to an aluminum alternative. This weight reduction translates to

a four million yen savings in costs per unit to get the rover to the moon, a substantial

effect in view of the standard cost of 100 million yen per kilogram transported. Given the

mission’s planned sequential launches scheduled to send a total of 100 units to the lunar

surface, it is imperative to reduce costs by reducing weight while achieving greater

strength.

Another key material from MCG is the regolith-proof coating agent to be applied to the

camera lens. This material is designed to solve the problem of regolith, the loose,

superficial deposits of ultrafine spiky dust particles measuring around 50 microns (one

twentieth of 1 mm) that blanket the surface of planets and moons, including the Earth’s

moon. Without this agent, regolith particles churned up by the rover as it moved across the

lunar surface would adhere to the camera lens, undermining the functionality of the camera,

which is essential for accurate data collection.

Akira Nakagoshi, who has been engaged in the development of pitch-based carbon fibers since

1985, spoke confidently about the technologies MCG is providing to the mission.

“On Earth, it is impossible to completely reproduce conditions occurring on the lunar

surface,” he explained. “But we conducted every experimental test possible according to

Dymon’s plan, giving each session our best. We conducted major experiments for a range of

strength analyses, which were performed at the Science Innovation Center at MCG’s R&D base,

for repeated testing for launch vibrations at Kyushu Institute of Technology, for test runs

using the facility owned by Uematsu Electric Co., Ltd. in Hokkaido that can create

one-second bursts of a simulated lunar environment with one-sixth Earth’s gravity, and for

additional test runs under simulated conditions on mock sandy surfaces in a vacuum.”

The YAOKI mission represents MCG’s first partnership with a space industry business venture.

Following the collaboration with Dymon, the company has begun talking with other players in

the sector.

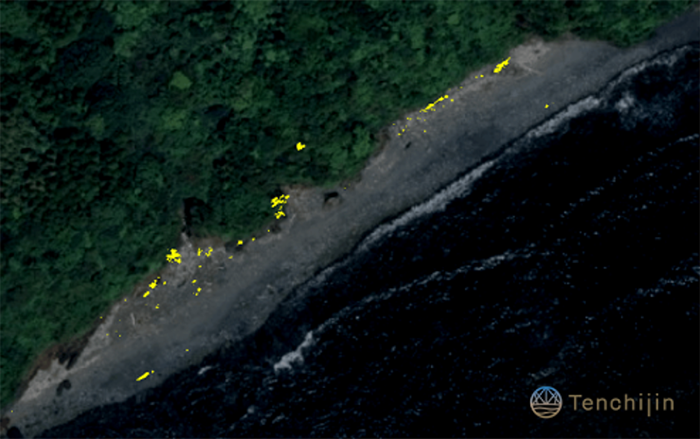

Younger teams starting space industry business projects to create new value

Satellite image showing identified marine plastic pollution

MCG has built a track record as a materials supplier to the space industry over many years,

starting with its carbon fibers that were adopted for the Cassini Saturn orbiter, which was

in service from 1997 to 2017. A more recent delivery was made to the ALMA radio telescope

project in the Andes in Chile—known for producing the world’s first direct image of a black

hole in 2019—when our pitch-based carbon fibers were employed for the framing of 50 primary

mirrors (major light collecting reflectors) supplied by US and European manufacturers among

the 66 radio astronomy dishes.

Based on the track record set out above, new actions have recently been initiated by six

employees seeking to expand the space-related business by capitalizing on the company’s

high-level technologies. The group of early- and mid-career employees formed a new business

creation project team following their launch of a program to promote the efficient

collection of marine plastic waste by utilizing artificial satellite data and recycling of

the collected plastic waste for space-related projects, such as building satellites. To

promote this program, the project team has formed a partnership with JAXA-sponsored startup

Tenchijin and the team led by Tomoyuki Miyashita, a professor in Waseda University’s

Mechanical Engineering Department (part of the School of Creative Science and Engineering’s

Faculty of Science and Engineering). Rie Nishida, a project team member, recalled the thrill

she felt every day when engaging in the space industry business.

“The space industry is a new field that cannot be developed by a single company,” she noted.

“So participating companies are working together rather than competing against each other.

It feels like there is a powerful momentum driving them all forward together.”

In Japan, the total national space budget amounts to 611.9 billion yen for fiscal 2023, a 90

billion yen increase from fiscal 2022. In a recent research report prepared by MUFG Bank,

the global space market is projected to grow from 56 trillion yen in 2023 to 91 trillion yen

in 2030. Nakagoshi shared his impressions on the future development of the space industry,

saying: “It’s great seeing the new business creation project team and the researchers

working with such passion and presenting lots of plans and ideas. But the challenge we have

is to create businesses from these ideas and promote future research and development.”

He went on: “The situation can be explained using the company’s slogan, ‘Science. Value.

Life.’ We are strong in ‘science’ and need to find ways to use that strength to create

‘value.’ This is the challenge we are tackling going forward. Based on the recent expansion

of deliveries to the YAOKI project, I expect that our extensive science-based capabilities

will be utilized effectively to generate added value that will contribute to the creation of

a society able to carry out more activities that involve putting humans in space.”

From August 4 to November 26, on the third floor of Tokyo Tower Foot Town, an exhibition took place under the title of “Operating the mock lunar rover YAOKI at CHUMS lunar base camp,” a collaboration co-hosted by the YAOKI project team and the outdoor outfit brand CHUMS. Nakagoshi described the significance of this event in light of the importance of inspiring children to take an interest in space and pursue their dreams in the field. Wanting to stimulate interest in the real YAOKI and nurture the dreams of many more children, the project has plans to hold similar hands-on events in the future.

INTERVIEWEE

AKIRA NAKAGOSHI

Composite Solutions Department

Specialty Materials Business Group

RIE NISHIDA

Coating Department

Coating & Additives Division

Polymers & Compounds / MMA Business Group

Mitsubishi Chemical Group Corporation

Palace Bldg., 1-1 Marunouchi 1-chome, Chiyoda-ku, Tokyo

Mitsubishi Chemical Group Corporation is a specialty materials group with an

unwavering commitment to lead with innovative solutions to achieve KAITEKI, the

well-being of people and the planet. We bring deep expertise and material science

leadership in core market segments such as mobility, digital, medical and food. In

this way, we enable industry transformation, technology breakthroughs, and longer,

more fruitful lives for us all. Together, around 70,000 employees worldwide provide

advanced chemistry-based solutions to deliver the core elements of our slogan —

“Science. Value. Life.”