2024.01.18

Mitsubishi UBE Cement endeavors to achieve significant reduction in CO2 emissions by adopting the world’s first ammonia co-combustion in cement manufacturing

Cement, an essential element for constructing our infrastructure, is made from an

intermediate material called clinker. Clinker is manufactured by sintering limestone with

the help of thermal energy provided by coal, which produces huge volumes of CO2 emissions.

Mitsubishi UBE Cement Corporation (MUCC) is undertaking a variety of initiatives to reduce

CO2 emissions, including co-combustion with waste construction materials and waste plastics.

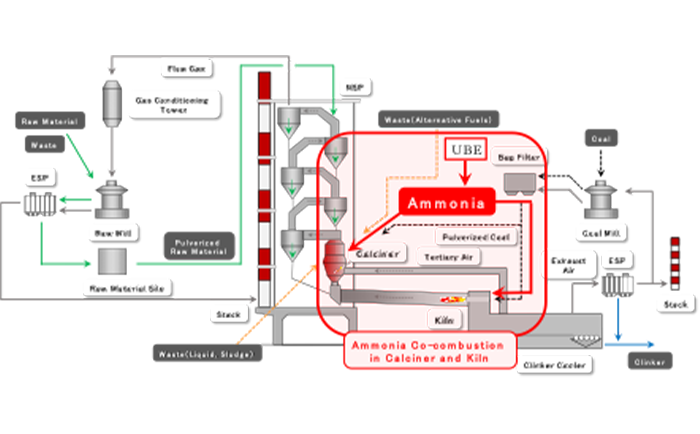

As part of its efforts, MUCC has begun a co-combustion test using ammonia to provide the

thermal energy required in a cement kiln (combustion furnace) and a calciner at its Ube

Cement Plant (Ube City, Yamaguchi Prefecture). This represents the world’s first attempt to

conduct co-combustion with ammonia using actual equipment at a cement manufacturing plant.

Technology planned to be established by the end of FY2025,

contributing to a significant reduction in CO2 emissions

Ammonia is drawing attention as a next-generation energy source due to its property of

emitting no CO2 when combusted. MUCC aims to raise the ammonia co-combustion ratio in

increments of 5%, to ultimately achieve 30%. If the targeted 30% can be achieved in a

practically feasible sense, the annual CO2 emissions derived from thermal energy at its Ube

Cement Plant can be reduced by 100,000 t from the current level of 350,000 t.

Takuya Kumagai from the Carbon-neutral Technology Promotion office, which was established

within MUCC’s Global Environment Preservation PJ, explained the co-combustion test as

follows:

“Adjacent to the Ube Cement Plant is UBE Corporation, which manufactures ammonia. Having an

ammonia tank and piping close to our plant is a great advantage in carrying out our ammonia

co-combustion test. Because ammonia co-combustion in cement manufacturing has never been

conducted before anywhere in the world, we must perform the test cautiously, starting from a

low co-combustion ratio. We do not just simply mix the ammonia in during combustion, but

also all the while check its impact on cement products and plant facilities and operation,

and consider whether to modify our fuel supply facilities by, for example, developing new

burners.”

The co-combustion test, dubbed the “Demonstration Project for Ammonia Combustion Technology

in Cement Manufacturing Process,” has been selected by Yamaguchi Prefecture as a recipient

of its FY2023 subsidy for carbon-neutral industrial complex construction. The test will be

conducted in two phases, the first of which, using a calciner, is scheduled for the second

half of 2024. The cement kiln combustion test will then be conducted in 2025, which will be

followed by data analyses and additional tests as necessary, with the aim of establishing

relevant technologies by the end of fiscal 2025.

Establishing Carbon-neutral Technology Promotion office to unify efforts across the entire company

Under its Medium-term Management Strategy, Infinity with Will 2025—MUCC Sustainable Plan 1st

STEP, MUCC set its interim targets and business strategy for 2030 toward carbon neutrality.

The company established the Carbon-neutral Technology Promotion office in August 2023,

assigning it the task of advancing the process development, demonstration and implementation

regarding carbon-neutral technology. Mr. Kumagai is also a member of the new department.

“Members of the Carbon-neutral Technology Promotion office are mainly process engineers,”

said Mr. Kumagai. “After joining the company, I worked at cement production sites for

several years. There, I became aware of the lack of organizations able to connect production

division with research and development center. Now, the Carbon-neutral Technology Promotion

office assumes this role.

“In addition to the ammonia co-combustion test, the department also undertakes projects on a

variety of carbon-neutral technologies including the low-cost, high-concentration recovery

of CO2 generated from raw materials in the cement manufacturing process for utilization as a

useful resource; methanation (i.e., synthesizing methane from hydrogen and CO2) and the

technology to use the output as fuel; and combining CO2 with calcium-rich waste to use as

construction and civil engineering materials. These are still laboratory-level technologies,

but our department will serve as a bridge between production division and research and

development center to move on to the demonstration stage with an aim to implement the

technologies at plants at the earliest possible timing toward the achievement of carbon

neutrality by 2050.”

The Global Environment Preservation PJ, with which the Carbon-neutral Technology Promotion

office is affiliated, hosts periodic briefing sessions to help employees better understand

carbon neutrality. This is because production division and research and development center

will need to join efforts to achieve the ambitious goal of carbon neutrality goal by 2050.

According to Mr. Kumagai: “MUCC was established by merging the cement businesses of two

companies—Mitsubishi Materials, a comprehensive materials manufacturer, and UBE

Corporation—so we have our own long-accumulated firing techniques for inorganic materials,

as well as an established supply chain. As for ammonia, we are capitalizing on UBE’s

expertise, working in close collaboration. Our major plants—the Ube Cement Plant, Kyushu

Plant (Miyako-gun, Fukuoka Prefecture) and Isa Cement Plant (Mine City, Yamaguchi

Prefecture)—are concentrated in coastal areas of western Japan that have large ports, which

provides us with an advantage in setting up supply bases for ammonia and other alternative

fuels. By leveraging these strengths, MUCC will serve as a hub to proliferate carbon-neutral

cement manufacturing and expand the infrastructure that underpins the endeavor.”

MUCC upholds the target of reducing CO2 emissions by 40% by 2030 (from the 2013 level). In

light of this aim, the company is anticipated to establish the world’s first co-combustion

technology and implement it in the real world before too long.

INTERVIEWEES

TAKUYA KUMAGAI

Carbon-neutral Technology Promotion office

Global Environment Preservation PJ

Mitsubishi UBE Cement Corporation

Iino Building, 2-1-1 Uchisaiwaicho, Chiyoda-ku, Tokyo

Established in 2021 by merging the cement and related businesses of Mitsubishi

Materials Corporation and Ube Industries, Ltd. (currently UBE Corporation).

Upholding its mission to “continue to support the future of the planet by providing

the highest quality with the best technology and services,” the company primarily

engages in domestic and overseas cement and ready-mixed concrete (RMC) businesses as

well as a limestone resource business, supplying safe and secure basic materials

required for developing physical infrastructure such as buildings, bridges and

roads.