2025.11.20

Mitsubishi Chemical and ENEOS Promote Chemical Recycling

the Plastic-to-Oil Conversion Business Launched at Ibaraki Plant

Mitsubishi Chemical Corporation and ENEOS Corporation are advancing the circular economy with new chemical recycling equipment at Mitsubishi Chemical’s Ibaraki Plant that facilitates a plastic-to-oil conversion business.

Mitsubishi Chemical and ENEOS held a ceremony to mark the completion of a chemical recycling facility they have been building since July 2021, which converts waste plastics into oil, at Mitsubishi Chemical’s Ibaraki Plant.

The new facility is expected to be a driving force in the companies’ plastic-to-oil conversion business with its annual commercial capacity of 20,000 tons, one of the largest in Japan. The waste plastic problem has become a global challenge. In Japan alone, waste plastics are now estimated to total 7.69 million tons. The companies aim to contribute to society’s transition to a circular economy.

The facility chemically breaks down externally sourced waste plastics and converts them into oil, utilizing hydrothermal plastic recycling technology developed by UK-based Mura Technology Limited. The technology, introduced to Japan for the first time, uses water at high temperature and pressure (supercritical water) as a solvent to break down plastics. Recycling process with supercritical water achieves a high yield by enabling uniform heat application that prevents gas generation from over-decomposition and char formation from localized heating. Furthermore, its minimal temperature variations allow for lower overall temperatures that lead to high energy efficiency.

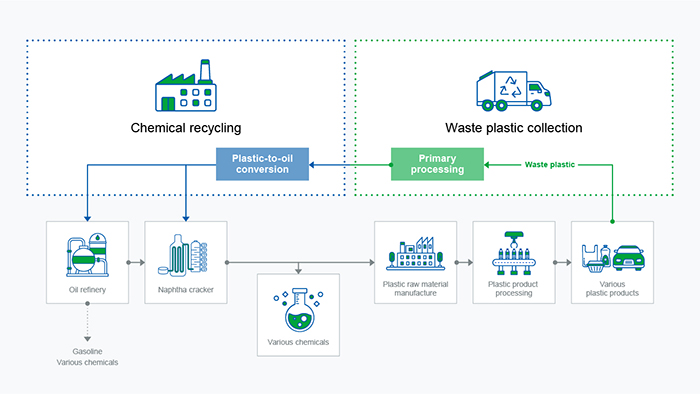

The resulting recycled oil is used by petroleum refining units and the naphtha cracker. Reprocessing it into petroleum products, various chemicals, and plastics will help advance the circular economy. The facility has obtained ISCC PLUS certification, awarded by one of the international certification systems for sustainable products.

Conceptual diagram of the plastic-to-oil conversion business supply chain

Chemical recycling born out of neighboring two companies

Both companies have facilities in the Kashima Coastal Industrial Zone of Ibaraki Prefecture, where Mitsubishi Chemical operates a basic chemicals manufacturing plant while ENEOS operates the Kashima Oil Refinery. As their plant sites are adjacent, they have maintained a long-standing relationship spanning approximately 50 years. Sho Takino, Mitsubishi Chemical’s CN/CE Business Group, CN/CE Strategy Department, Strategy & Planning Division, Basic Materials & Polymers Business Group, reflects:

“Not only we are part of the same Mitsubishi Group, but also ENEOS and we have a long, close relationship from before then. As our facilities are next to each other in Kashima and our businesses involve petroleum refining and petrochemicals, we have long deepened our collaborative relationships. We haven’t done a joint chemical recycling initiative before, but we are uniquely suited for building facilities together and distributing the necessary quantities to each other.”

Chemical recycling plant (Mitsubishi Chemical Ibaraki Plant)

The joint project combined conventional and new technologies, utilizing as much existing infrastructure as possible. Recycled oil cannot be supplied to the market as is, and must be reprocessed into petroleum products, chemicals, and plastics. If additional cost of constructing facilities for such reprocessing were required, the cost would inevitably be reflected on product prices.

Hajime Kojima of the Basic Chemicals Planning Group, Basic Chemicals Planning Department at ENEOS, says: “Our ultimate goal is to create a circular economy, so it is important to build recycle plants that minimize environmental impact as much as possible while effectively utilizing existing plants and recycling systems.”

The new facility can recycle waste plastics

into products with virgin quality

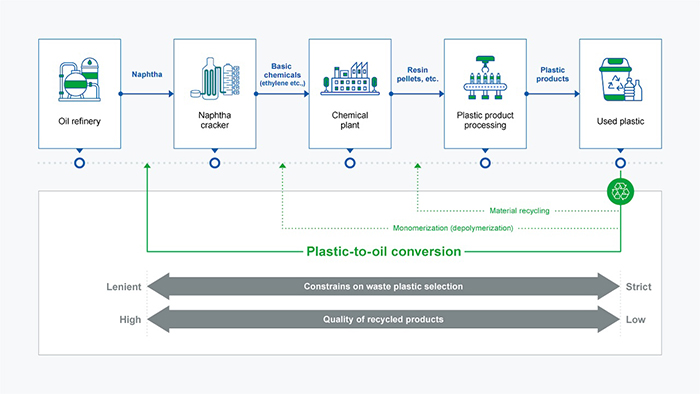

Plastic-to-oil chemical recycling

The significance of this recycling process lies in its abilities to process waste plastics containing different types of plastics into a final product that can be used as feedstock, and to produce plastic that is as good as new.

Mr. Takino explains: “In the typical example of today’s PET bottle recycling, the caps and labels are removed after collection, and foreign objects are taken out. The bottles are then crushed into flakes and remolded into the recycled PET bottles.

Therefore, mechanical recycling requires thorough sorting. It’s also challenging to restore plastic film to transparency. This means that the resulting plastics are often recycled into items like park benches or clothes hangers. And they cannot be used for medical products or food packaging, which are subject to stringent regulations because they come into contact with people’s mouths. The newly completed plant can recycle used plastics that couldn’t be recycled with conventional technology back to a quality that is comparable to virgin (new) plastic.”

“If the expertise and know-how of both petroleum refining and petrochemicals can be mutually leveraged, it will accelerate problem-solving and, in the future, expand the possibilities for plastics derived from chemical recycling.” adds Mr. Kojima.

What impact will the plastic-to-oil chemical recycling promoted by Mitsubishi Chemical and ENEOS have on society?

“Awareness of chemical recycling is still low, and the public needs to learn more about it,” Mr. Kojima states. “By helping them learn chemical recycling, we hope to promote a circular society together.”

“There is a growing sentiment among people against throwing away plastic waste,” Mr. Takino remarks. “It is our mission to reuse plastic waste as a resource.”

INTERVIEWEES

Sho Takino

Manager

Mitsubishi Chemical Corporation

CN/CE Business Group, CN/CE Strategy Department, Strategy & Planning Division, Basic Materials & Polymers Business Group

Hajime Kojima

ENEOS Corporation

Basic Chemicals Planning Group

Basic Chemicals Planning Department

Mitsubishi Chemical Corporation

Palace Bldg., 1-1-1 Marunouchi, Chiyoda-ku, Tokyo

ENEOS Corporation

1-1-2 Otemachi, Chiyoda-ku, Tokyo

Mitsubishi Chemical Corporation, established in 1933, is a comprehensive chemical manufacturer that provides a wide range of materials, from basic chemicals to performance products. The company operates globally across diverse fields including mobility, semiconductors and communications, food, medical, and infrastructure. Mitsubishi Chemical aims to be a “Green Specialty Company” committed to solving social problems and to delivering impressive results to customers with the power of materials, under our Purpose that “We lead with innovative solutions to achieve KAITEKI, the well-being of people and the planet.”

At ENEOS Corporation, our network has grown to about 12,000 ENEOS branded service stations across Japan. We are expanding business to accommodate energy transitions into sources like hydrogen and Synthetic Fuels in addition to petroleum and petrochemical products produced and manufactured at refineries and factories at various locations in Japan. The ENEOS Group aims to achieve both a stable supply of energy and materials and the realization of a carbon-neutral society, based on its commitment of “Supporting ‘today’s normal,’ taking the lead for ‘tomorrow’s normal.’”