2026.01.22

Recycled Metal Brand REMINE Featuring a Lineup of Six Products Mitsubishi Materials Corporation Helps Design a Recycling-Oriented Society Through Japan’s First Initiative

Mitsubishi Materials Corporation is expanding the recycled metal brand of REMINE, which is the first initiative of its kind in Japan. The company is enhancing information transparency and traceability while facilitating resource recycling and the reduction of environmental impacts. What does it aim to achieve?

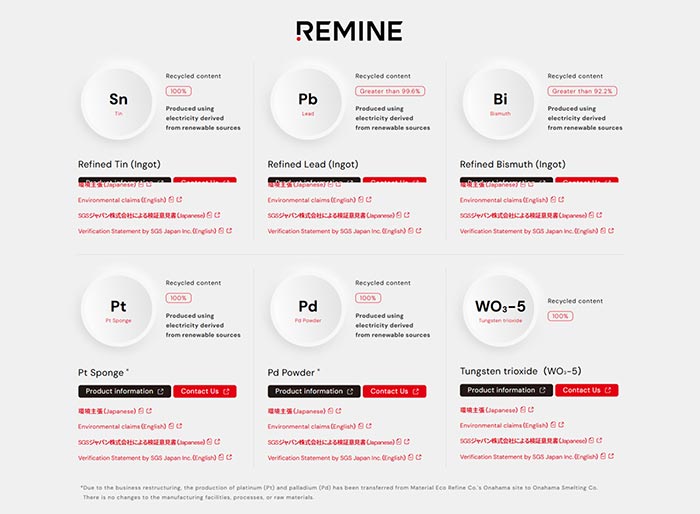

Launched in January 2024 by Mitsubishi Materials Corporation, REMINE is Japan’s first recycled metal brand. Full-scale operations have begun, and the brand is attracting attention. Beginning with the sales of refined tin (Sn) (ingots) and refined lead (Pb) (ingots) as the first products in the series, the lineup currently consists of six products, with the addition of refined bismuth (Bi) (ingots), platinum (Pt) sponge, palladium (Pd) powder, and tungsten trioxide (WO3-5). The company plans to further expand the lineup of REMINE, which promotes resource recycling and is one of the company’s most promising brands.

Resource recycling and the reduction of environmental impacts are gaining heightened attention in the quest to achieve a sustainable society. In particular, supply chains are increasingly required to ensure the transparency and traceability of raw material information as part of their responsibility to stakeholders, with efforts to quantify the environmental impact of products becoming even more essential.

The REMINE brand was launched in January in response to such social needs, and it creates new value based on the recycling technologies that the company has long cultivated. A key feature of the brand is that the recycled content is calculated in accordance with the international standard ISO14021 and verified by third-party organization SGS Japan Inc., thereby ensuring higher reliability. Saori Koga, General Manager of the Planning Sector in the Business Development Department, Resource Circulation Division, explains:

“Many other companies around the world are using recycled raw materials, just as we do. However, there was no system for third parties to objectively verify the actual implementation of such recycling. To create new value in recycling, we developed a system that focuses on information transparency and traceability. This enabled us to deliver new value and peace of mind to our customers, and we have turned it into a brand.”

REMINE brand products are manufactured using electricity generated from renewable energy

We created the REMINE brand name by combining the suffix “re-,” from “repeat/reborn” with the word “mine.” The brand logo is a registered trademark, with the red circle symbolizing that it is made in Japan, and the logo’s angles aligned with those of the diamond shapes constituting Mitsubishi’s logo. The REMINE brand reflects the idea of recycling metal resources collected from used products or process waste, likening these recycled materials to the mines of a new era. Behind this idea lies our strong desire to pass on the value of metals to the next generation and to contribute to a more prosperous future for people, society, and the Earth .

REMINE complies with ISO 14021, the international standard for “Environmental labels and declarations—Self-declared environmental claims (Type II environmental labelling).” This standard specifies the definitions of recycled materials and the methods for calculating recycled content, among other related requirements. We also have our calculations verified by the third-party organization SGS Japan Inc. This framework and concept represent the first initiative of its kind in Japan.

The six-product lineup of the REMINE series

In January 2024, as the first products in the lineup, REMINE introduced refined tin (Sn) (ingots) containing 100% recycled material and refined lead (Pb) (ingots) containing 99.6% or more recycled material. In December 2024, the series expanded to include four additional products: refined bismuth (Bi) (ingots) with a recycled content of 92.2% or more, and platinum (Pt) sponge, palladium (Pd) powder, and tungsten trioxide (WO3-5), each made from 100% recycled material. Among the six products, five—excepting only tungsten trioxide (WO3-5)—are manufactured using electricity generated from renewable energy, and we aim to increase the use of such electricity to virtually 100%.

To build a recycling-oriented society where recycling is easy

Koga underlines that this initiative has been underway for a long time.

“Our company has long been collecting metals from used electronic devices and other equipment, accumulating extensive know-how and expertise. Sustainability has gained

greater attention over the past five years or so, and as customer needs aligned with our recycling technology, we decided to relaunch our existing efforts as a brand.”

REMINE series products are used for various applications. Among those familiar in daily life are tin (Sn) for solder, lead (Pb) for vehicle batteries, bismuth (Bi), a rare metal, used in low-melting-point solder for electrical and electronic equipment, platinum (Pt) and palladium (Pd) for jewelry and for exhaust gas catalysts in internal combustion engine vehicles, and tungsten trioxide (WO3-5) for batteries and as a raw material for the cemented carbide tools our company manufactures in its Metalworking Solutions Business. Tin currently has the greatest demand, while lead has the highest production volume. Koga shares her thoughts on REMINE:

“Most people probably have no idea how discarded items are recycled or what products they become. For example, few people are likely to know how a laptop they throw away is recycled or what it ultimately turns into. We would be delighted if the REMINE brand encourages people to take a greater interest in what happens to their discarded items.”

By supplying REMINE series products, Mitsubishi Materials Corporation will continue contributing to the achievement of a sustainable society.

INTERVIEWEES

Saori Koga

General Manager

Planning Sector

Business Development Department

Resource Circulation Division

Mitsubishi Materials Corporation

Marunouchi Nijubashi Building 3-2-3 Marunouchi, Chiyoda-ku, Tokyo

Founded in 1871 and incorporated in 1950, the company has 18,452 consolidated employees and 5,315 employees on a standalone basis. Tracing its roots to the mining business launched by the Mitsubishi Group’s original company of Tsukumo Shokai, it has contributed to the modernization of Japan for more than 150 years. Its legacy includes the modernization of historical sites such as the Sado Gold Mine, one of Japan’s most famous gold mines, and Gunkan Island, which became widely known through a popular TV show. The company adopted its current name, Mitsubishi Materials Corporation, in 1990. It is primarily engaged in businesses such as copper smelting, metal processing, and geothermal power generation.